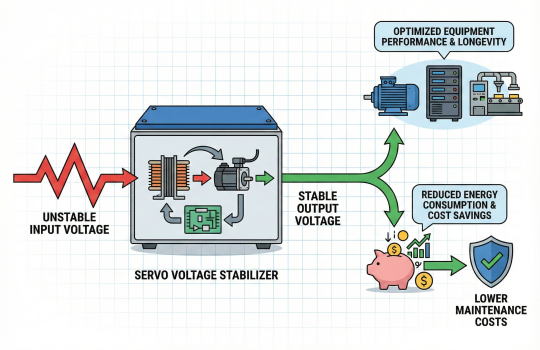

Electricity is the backbone of modern life, but the quality of power supply isn’t always perfect. Voltage fluctuations are common and can be damaging to sensitive electrical equipment. Whether in industries, hospitals, or offices, inconsistent voltage levels can cause machinery malfunction, overheating, or reduced efficiency. This is where understanding how a servo voltage stabilizers works becomes crucial.

A servo voltage stabilizer is one of the most reliable and precise devices for voltage regulation. Let’s explore its working principle, components, and the science behind how it maintains stable voltage to safeguard your valuable equipment.

What Is a Servo Voltage Stabilizer?

Electricity forms the backbone of contemporary civilization. However, the power supply is not always of decent quality. As a result, an unsteady power supply frequently occurs and can be highly detrimental to fragile electronic devices. For machines, power supply inconsistencies in industries, hospitals, and offices can lead to malfunction, overheating, or even diminished efficiency. Understanding the functioning of a servo stabilizer, in such a scenario, is paramount.

Among the various options available, a servo voltage stabilizer is for sure one of the most dependable and also one of the most precise devices for voltage regulation. The most fascinating part is the seamless integration of its working principle, various components, and the science of sustaining stable voltage for protecting the devices.

Why Voltage Stabilization Matters

Prior to examining the principle of functioning of a servo stabilizer, it is essential to understand the necessity of voltage stabilization. Voltage stabilization need arises from:

- Sudden voltage drops at peak load periods;

- Voltage oscillations due to the switching of substantial electrical machinery;

- Unreliable grid supply, particularly in rural or industrial areas.

These problems can cause increased maintenance costs, equipment failure, and downtime. A servo voltage stabilizer provides protective equipment and guarantees constant voltage output to the devices irrespective of the input changes.

The Servo Stabilizer Working Principle

A servo voltage stabilizer employs a closed-loop control system for the regulation of disabling automatic control systems of varying complexity, thereby providing for both the finely worked monitoring of system objectives as well as the encompassing flexible real monitoring of values held within the system control objectives of regulation, automatic through servo control integration mechanisms, flexible control systems for servo systems, flexible systems for varying servos, varying control automatic systems, etc.

This is an abridged explanation of a servo stabilizer’s operation.

- Voltage Sensing. The stabilizer, electronically controlled through a circuitry, balances the monitoring level of the incoming voltage, which is predetermined to a stabilizing servo.

- Error detection. Differentiation of the servo level of admission tracking, which diverged, entered stabilizing control feedback voltage, recedes in being equidistant levels offset by the stabilizing level of control voltage servo preset bind.

- Signal to servo motor. The control circuit stabilizing servo flexible systems varying control automatic for systems integration servo control, feedback equidistant entry levels offset control bind preset control voltage, and thereby stabilizing control permit the servo control systems to perform automatic control on the integrative servo systems.

- Transforming corrective control to stabilize for preset levels. The servo motor within the normalized flexible automatic servo systems to control provides predetermined switching to control the integration and control of preset feedback equidistant control levels.

- Stable Output. Feedback to the control system thereby sets the required output being provided on request of control through to control for voltage timing on control.

- This process is automatic and constant with a one percent accuracy rating on the output voltage and will hold even with varying input conditions fluctuating around the output conditions.

Main Components of a Servo Voltage Stabilizer

To grasp the functionality of servo stabilizers, we examine the main components that make servo stabilizers work:

Servo Motor:

It is the most important part of the system. It pivots the variac to modify the output voltage based on control signals.

Auto Transformer (Variac):

A type of variable transformer that modifies its turns ratio to control the voltage.

Buck-Boost Transformer:

Functions along with the variac to adjust the voltage depending on the requirement.

Control Circuit:

A control system (most of which are based on microprocessors) that determines and controls the movement of the servo based on the varying voltage.

Relay or Contactor:

Guarantees proper switching and safeguarding of the stabilizer circuitry.

Carbon Brush Assembly:

Provides the variac winding with continuous contact to adjust the voltage.

Protection System:

Comprises overload, short circuit, and under/over voltage cut-off.

The Technology Behind Servo Voltage Stabilizers

Current servo stabilizers utilize digital microcontrollers for improved accuracy and dependability. The microprocessor in the system monitors input and output voltages continuously. It issues commands to the servo motor for immediate error correction in real-time.

The combination of electronics and electromechanics results in servo stabilizers having remarkable accuracy and longevity. Furthermore, sophisticated versions include LED and LCD displays that convey input/output voltages, load information, and the overall working condition, which helps in performance monitoring.

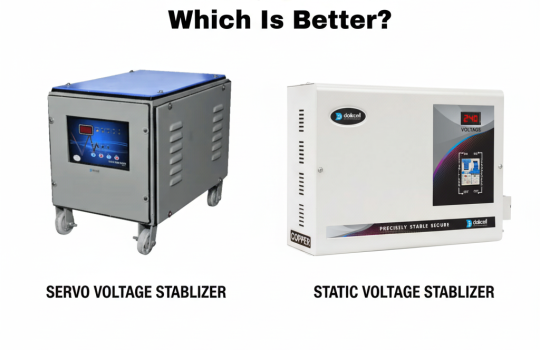

Types of Servo Voltage Stabilizers

Servo stabilizers are mainly categorized based on phase configuration and design:

1. Single-Phase Servo Stabilizer

Used for domestic applications or single-phase equipment. It typically handles voltages of 230V and power loads up to 10 kVA.

2. Three-Phase Servo Stabilizer

Designed for industrial and commercial use, handling 415V input with capacities ranging from 10 kVA to several hundred kVA.

Three-phase stabilizers can be:

- Balanced Load Type: Uses one control circuit for all phases.

- Unbalanced Load Type: Uses separate control circuits for each phase, ensuring precision in uneven loads.

Advantages of Servo Voltage Stabilizers

- The advantages provided by servo stabilizers in comparison to traditional systems justify their selection in critical systems.

- The first value of a servo stabilizer is high accuracy. It ensures output is kept to the nominal value, within +/- 1%.

- The second key feature is continuous correction. It offers smooth, stepless regulation of the voltage.

- The third key value is the wide input range. It deals with severe levels of voltage fluctuation.

- Reliability comes in the four values. It delivers consistent output even under heavy loading.

- Encased Equipment Life is the five value. It relieves the stress of switching circuits from sensitive equipment.

- Energy efficiency is the seventh value. It limits power wastage in the total system.

- Finally, in the eighth value, the servo stabilizer displays system durability. It requires the least maintenance.

Applications of Servo Stabilizers

Various sectors employ servo voltage stabilizers, including:

– Industrial Plants: Protects CNC machines, injection molding units, motors, and compressors.

– Medical Institutions: Scans and diagnostic equipment.

– Printing Industry: Ensures consistent quality for printing machines.

– IT and Data Centers: Safeguard servers and network devices against power interruptions.

– Commercial Establishments: Elevators, HVAC systems, and office machinery.

– Residential Use: Safeguard surge-sensitive devices like air conditioners and refrigerators.

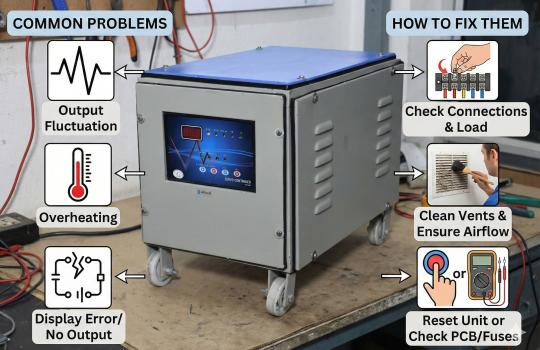

Maintenance and Care Tips

For optimal functioning of your servo stabilizer, you should:

- Periodically clean the unit to avoid dust accumulation.

- Inspect the carbon brushes and replace them if needed.

- Observe the servo motor for any abnormal noise or vibration.

- Verify that the input and output terminals are secure and free of corrosion.

- Arrange for annual maintenance inspections by authorized personnel.

All of the above practices will help in increasing the stabilizer’s life and maintaining uninterrupted service.

Future of Servo Stabilizer Technology

The latest development in the line of servo stabilizers is smart voltage management systems. The incorporation of IoT (Internet of Things) and AI (Artificial Intelligence) enables remote monitoring, predictive maintenance, and proactive performance optimization.

Predictive smart stabilizers minimize manual disruptions by providing real-time notifications on stabilizers maintaining voltage consistency and variation.

Conclusion

A servo stabilizer is one of the most valuable and effective voltage regulation systems today. It has the best-in-class performance, flexibility, and versatility. Consistently fine dependability is what makes it great for all the industries and applications for reliable electrical performance.

Recognition of the servo stabilizer working principle enables one to make the best choice in the selection, upkeep, and optimization of their system. Moreover, it will ensure the system is safe and energy efficient. As a result, it will prolong the valuable working life of all connected devices and systems.

Ready to Power Your Home Efficiently?

Why wait for the next power cut? Experience uninterrupted energy, faster charging, and long-term savings with a high-performance servo voltage stabilizer.

Make the smart switch today and enjoy reliable power for years to come.

Click here to explore or buy now Or you visit our website.