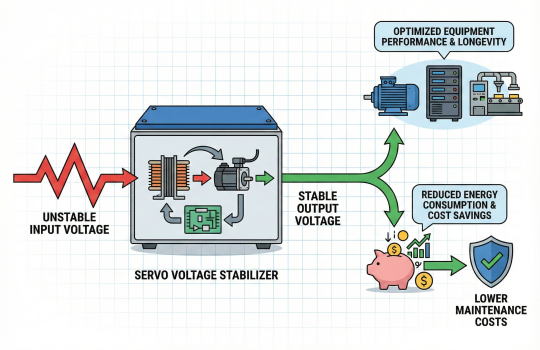

The ability to operate without interruptions has become a key requirement for continuous production in the modern industry. Damages to equipment, inefficiencies, and rising costs of equipment maintenance are all a result of unanticipated changes in voltage. For this reason, businesses in the industry depend on sophisticated voltage stabilizers to guarantee the protection of their assets. This blog focuses on the importance of the benefits of using a servo voltage stabilizer on the operational lifespan, productivity, and safety of industries.

-

Understanding Industrial Power Challenges

Unpredictable fluctuations in voltage occur in almost all industrial regions. This is a result of the dynamic load, deployment of industrial-grade machines, and power supply distribution irregularities. Such variations in voltage can adversely affect the operational ability and functionality of several pieces of equipment, including, but not limited to, motors and automation machines, CNC equipment, packaging machines, and compressors. This calls for industries to seek systems with the ability to provide uninterrupted and lockdown voltage control to prevent operations from exposure to risk.

-

Improving Safety within Industries

The presence of electrical and overheating risks often makes the factory an unsafe place to be. Industrial and manufacturing environments are less safe due to the electrical surges present. Sudden surges can lead to overheating of machines, mechanical failures, and even fires. Risk of electrical fires and overheating of equipment in machines can be minimized through the installation of a stabilizer. This powerful tool allows industries to take a step toward improved operational safety and better protection of their personnel from the electrical hazards associated with large industrial machines.

-

Extended Equipment Lifespan Using Stabilizers

Industrial equipment is costly, and replacing parts is also quite expensive. However, a stabilizer assists in protecting machines by relaying the appropriate voltage levels, protecting machines’ motors, meters, drives, and control circuits from voltage-related failures, which in turn assists in prolonging the equipment’s operational lifetime.

-

Energy Efficiency and Cost Savings

Stabilizers enhance operational efficacy by reducing electricity wastage and preventing motors from overheating. Providing a factory with constant levels of voltage further prevents unnecessary expenses from power loss and, in turn, provides long-term economic savings.

-

Boosting Productivity Through Reliable Power

With a trustworthy and consistent power supply, production runs smoothly with no interruptions. Stabilizers enhance the power supply to ensure machines keep operating without power-related stoppages, which improves productivity and completes manufacturing processes in shorter time frames.

-

Advantages of Using Modern Stabilizers

Modern stabilizers have features like microcontroller-based control, overload protection, fast correction speed, and more, which make them suited for industries with automation, robotics, and large motor applications.

7. Benefits Of An Industrial Servo Voltage Stabilizer

An industrial voltage stabilizer protects against breakdowns of power disturbances. Protects against equipment breakdown and overheating. Moreover, it allows power delivery during peak load and enhances factory performance and minimizes operational disruptions.

-

Understanding of Servo Technology in Modern Stabilizers.

Servo stabilizers incorporate a specific servo motor to control the voltage. These stabilizers are defined in measurable outputs and perfect voltage contents. These industries are required to be sensitive with advanced electronic equipment.

-

Why Factories Prefer a Servo-Based Solution.

Fast correction speed and stabilization, high efficiency output, and the fundamental ability to maintain under jerky power supply make factories prefer servo-based stabilizers. These instruments are considered ideal under high operational loads.

-

Servo Stabilizer for Factory.

A servo stabilizer for a factory protects all manufacturing machines by providing consistent as well as specific balanced voltage control. Protects CNC and plastic molding machinery, packaging lines, and HVAC systems in factories. For those industries aiming to achieve zero downtime, the superior balance and durability characteristics of servo stabilizers make them the most advanced solution.

-

Industries That Benefit from Voltage Stabilizers

Numerous sectors such as textiles, plastics, tablets and capsules, food processing, automotive, chemicals, and metal fabrication rely on the usage of stabilizers. Every industry that has high-end machinery and automation in their processes depends on stabilizers for safety and reliability of the operation.

-

Choosing the Right Capacity for Your Industry

When it comes to stabilization, the right capacity to choose depends on the specifics of the load the machinery will be using, the amount of fluctuations that will be experienced, and the working conditions of the environment as well. Stabilizers that are oversized will result in needing to spend too much on unnecessary things, and the opposite will happen in terms of cost as well as protection if the stabilizers are too small. A professional site evaluation will be very useful in determining the best capacity.

-

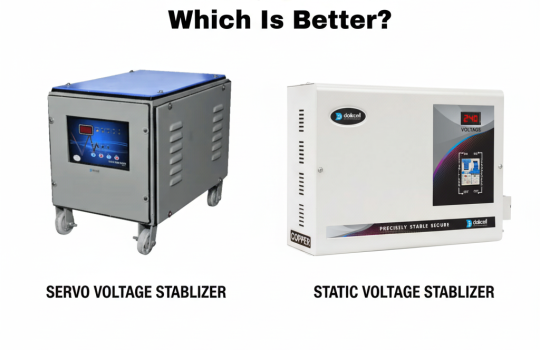

Servo vs. Static Stabilizers: Which Is Better?

When it comes to voltage stabilization, both servo and static stabilizers will do the job. But in industrial settings servo stabilizers will outperform static stabilizers in both precision and performance. In the case of less light loads, static stabilizers will work best, as they are fast. Industries that have very important equipment often go for servo models in order to achieve better stability.

-

Installation Requirements for Industrial Stabilizers

Some of the requirements of stabilizers are proper ventilation, sufficient working space, and the correct way of wiring. Professionals need to be sure that grounding, earthing, and panel connectivity have been checked to guarantee the stabilizers will be integrated into the industrial systems in a seamless way.

-

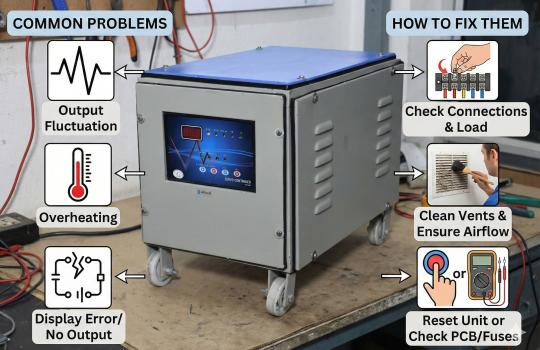

Maintenance Tips to Keep Stabilizers Running Smoothly

The best form of maintenance that will help stabilizers provide the performance that you need is regular inspection. Maintenance will also help to improve the longevity of the stabilizers, from cleaning filters and ventilation systems to checking input and output voltage to lubrication of parts in the case of servo models and replacing parts that are worn out. In order to keep machines fully protected, maintenance will need to be done on a scheduled basis.

Conclusion

Voltage stabilizers are more than protection devices for electrical safety; they are critical components for modern industrial advancement. If you seek to improve the longevity of machinery, increase productivity, or reduce breakdowns, the value of a stabilizer is immeasurable. There is minimal interruption, greater efficiency, and tremendous savings for industries reliant on servo stabilizers and sophisticated systems of voltage management. The appropriate stabilizer will revolutionize the performance of your factory. The gains will be compounded, and so will be the benefits.

Ready to Power Your Home Efficiently?

Why wait for the next power cut? Experience uninterrupted energy, faster charging, and long-term savings with a high-performance servo voltage stabilizer.

Make the smart switch today and enjoy reliable power for years to come.

Click here to explore or buy now Or you visit our website.