Voltage variation affects residential homes, retail shops, manufacturing units, and industrial plants. It especially impacts sensitive equipment such as CNC machines, medical devices, HVAC systems, and production printers that require a stable and constant voltage. This is the moment when the need to have a servo voltage stabilizer comes into play. With numerous options and specifications to choose from, the process of indenting and customizing the right stabilizers can become complex. This comprehensive cluster blog will assist you with the process of customizing and indenting the right servo voltage stabilizer to match your requirements.

Understanding the nature of voltage fluctuation and the damage it can cause.

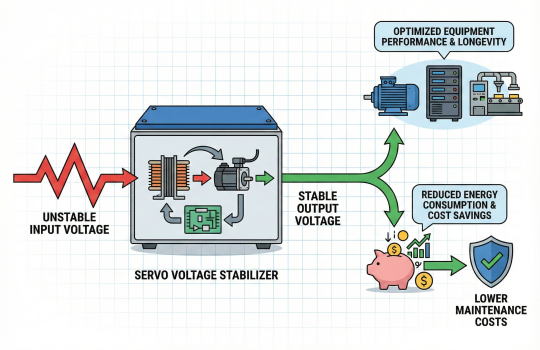

Voltage fluctuation, as the telecommunications regulator describes, is when the electrical supply is allowed to vary, i.e., being undersupplied, oversupplied, or a combination of the two simultaneously. If the electrical supply is allowed to fluctuate, one will experience the phenomena termed as “low voltage” and/or experience “high voltage.” Each of these phenomena can adversely affect and damage your critical electrical devices and machinery and appliances. Low electrical supply can overheat and cause the equipment to consume more power as well as reduce the overall output efficiency. On the contrary, equipment can be burned and/or permanently destroyed if the electrical supply is allowed to be high. A servo voltage stabilizer is able to continuously maintain constant electrical output, irrespective of the input voltage, and provides protection for your equipment with operational continuity. Knowing the voltage stabilizer needed to be purchased comes from understanding the nature of the fluctuations in your area.

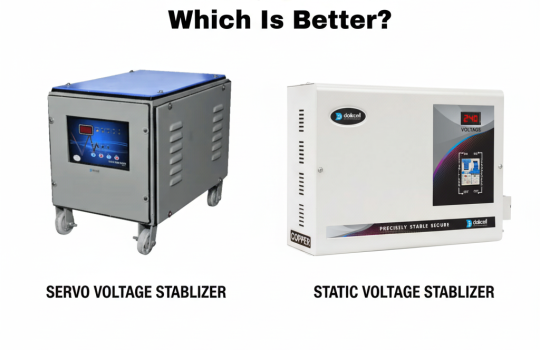

Advantages of servo stabilizers over other voltage stabilizers

Compared to static and relay-type stabilizers, servo motor stabilizers have higher accuracy and correction speed and last longer. With their mechanisms, servo stabilizers have more accuracy to keep output current stable and have more consistency to ensure a safe functioning range. For these reasons, servo stabilizers are more standard in higher performance systems, especially in systems that require stable voltage to ensure their performance. They are more standard in systems that need constant voltage stability, as they are more reliable.

Load Calculation—The Most Important Step

Calculation of load is very important, as it is the groundwork for selecting an appropriate stabilizer. Prior to the purchase, the total wattage or KVA rating of the systems that require protection should be ascertained. Keep in mind that to cover for possible future load increases or higher-than-expected load spikes, an additional 20 – 25% of capacity is highly suggested. For example, in a situation where a piece of equipment is rated to require 20 KVA, it is advised to purchase a servo stabilizer in the range of 25 to 30 KVA. Effective load calculation will ensure that the stabilizer does not face aggressive overheating action as a result of poor load calculation.

Limitations with Region and Input Voltage Range

To determine which stabilizer to use with your system, one would first have to determine what kind your area is working with. Some areas have more severely unstable voltages than others, which is where the fine distinctions of servo stabilizers come in with input ranges of 140V–260V, 160V–270V, and 70V–300V. Determining the input range is critical in them being able to stabilize and offer the most value. Furthermore, an area with severely low voltages would require a wider range of stabilizers to offer high levels of consistency in filling output voltage.

Added Features and Control

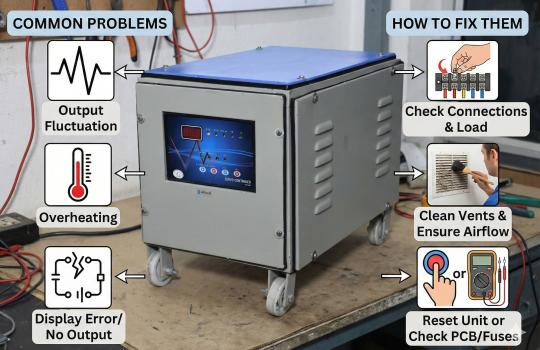

To manage and maintain the correct voltages of the servo stabilizers to reliably and accurately correct the voltages in a more advanced way, new technology is being utilized. The new technology has control panels, automatization, protection alarms, and digital. Several devices have additional protective features. Some overload, short circuit, bypass, and diagnostic features—one would encourage having these protective features to protect the stabilizer and the devices connected to it.

Efficiency and Power Consumption

For industries and commercial establishments running stabilizers 24/7, energy efficiency becomes a major concern. High-efficiency stabilizers are more consistent in performance, reduce electricity bills, and generate less heat. Look at efficiency ratings above 95% and note that models with copper windings perform better in efficiency than those with aluminum windings. In the long run, a stabilizer that consumes less power translates to a positive cash flow.

Brand Reliability and After-Sales Support

A servo stabilizer is a long-term investment, and brand reliability is arguably the most important in performance and durability. Make a point to choose these brands, who, over the years, have built a reputation for high-quality system manufacturing, solid components, and experience in the field. After-sales service is equally important. Brands with quick installation support, easy spare availability with their service, and good Service Level Agreements are always better. Having an established and reliable after-sales service results in minimal downtime and optimal satisfaction.

Considering Total Cost of Ownership

While most customers consider the price tag, they forget to consider the cost of ownership in the long run. This includes energy consumption, recurring maintenance, service downtime, and the costs associated with inoperability. In the long run, a stabilizer that is slightly more expensive but more efficient with better components becomes cost-effective. Go for solutions that add value to the system over just low price.

Application-Essential Selection for Home, Office & Industry

The type of stabilizer that you need to buy for your application or usage greatly differs from one another. In homes, a stabilizer for AC, refrigerators, TVs or other low-capacity models is common. Small offices or businesses may require a stabilizer for their computers, servers, and other retail equipment. While for industries, there is a need for heavy-duty stabilizers that are compatible with CNC, VMC, medical devices, and printing and production machines. So, you need to define your specific environment before making a purchase.

Professional Consultation and Site Survey

For high capacity and industrial needs, it is always recommended to take a professional consultation or site survey. To provide their clients with the best stabilizer for their needs, experts look at the load profile, the voltage situation, the wiring configuration, equipment specifications, and other factors to provide the best recommended stabilizer. This lowers the possibility of mismatch and guarantees optimal usage. Free site surveys are offered from manufacturers and authorized dealers, and it helps secure the best configuration for your needs.

Follow a Proper Custom servo stabilizer selection guide

In case you need to buy a stabilizer, it is encouraged to follow a proper custom servo stabilizer selection guide. To improve your approach, follow these steps: assess voltage fluctuations, estimate load capacity, determine the input voltage range, compare efficiency and features, check brand credibility, and consider cost. This ensures the stabilizer matches your system requirements perfectly and delivers optimal protection and reliability over time.

Criteria for Selecting the Quality Servo Voltage Stabilizer

When choosing a quality servo voltage stabilizer, key factors to consider include brand reputation, warranty period, customer feedback, build quality, technology, and your specific requirements The best stabilizers usually feature microprocessor control, overload protection, a wide voltage operating range, high efficiency, copper windings, and dependable customer support. A stabilizer with such features will save you a lot of money in the future.

Conclusion

To enhance operational efficiency and safety and to avoid downtime, it is important to have the right Best Servo Voltage Stabilizer. Having a proper analysis of the load requirements, voltage conditions, and reliable brand will help you choose the best model. A well-designed stabilizer ensures uninterrupted electricity, protects your equipment, and provides satisfaction in your work. This applies to homes, offices, and industries alike.

Ready to Power Your Home Efficiently?

Why wait for the next power cut? Experience uninterrupted energy, faster charging, and long-term savings with a high-performance servo voltage stabilizer.

Make the smart switch today and enjoy reliable power for years to come.

Click here to explore or buy now Or you visit our website.